AUTO DRAIN VALVE

♦ More than 2 Lakhs Installations

♦ Designed specially to drain sludge and rust laden condensate

♦ Reliable all digital electronic circuitry

♦ ON and OFF timing adjustable

♦ Power & Drain status indicator

♦ Extended cycle time up to 32 hrs adjustable

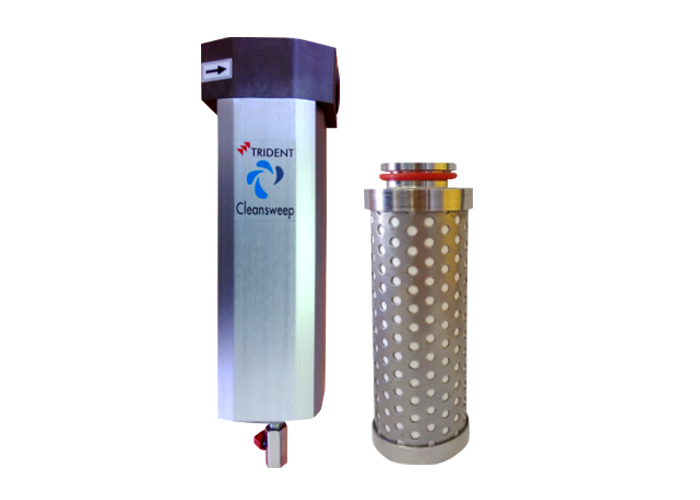

BACERITA FILTER

♦ Trident cleansweep series of bacteria filters provides protection from bacteria in compressed air applications for medical and food industries.

♦ Aluminium alloy housing, hard anodized for corrosion resistance.

♦ Borosilicate filter media and stainless steel filter element construction, compatible with autoclave sterilisation.

Technical Specifications

| End Connections BSP | Item Code | Rated Flow scfm | Dimensions | Max. Working Pressure kg/cm2 | Spare kit Item code | |||

| A | B | C | ||||||

| T100B | ½" | PFB01 | 60 | 87 | 280 | 300 | 16 | AS928 |

| T250B | 1" | PFB02 | 150 | 114 | 385 | 350 | 16 | AS929 |

| T600B | 1½" | PFB03 | 350 | 114 | 461 | 420 | 16 | AS930 |

| T851B | 2" | PFB04 | 500 | 148 | 646 | 600 | 16 | AS931 |

| T1210B | 2" | PFB05 | 710 | 148 | 716 | 670 | 16 | AS932 |

| T1810B | 3" | PFB06 | 1065 | 211 | 734 | 670 | 12 | AS933 |

HIGH PRESSURE FILTER

♦ Oil Removal (Coalescing) and Particulate

♦ Flow from 90 scfm to 800 scfm

♦ Particle Removal 0.01 (μm)

Technical Data

| Model | Element Grade | Drain Type | Pipe Size BSP | Flow Rate (scfm) | Max Working Pressure kg/sq.cm. | Housing Dimensions (mm) | ||

| A | B | C | ||||||

| T 100-40 | P / X / Y / A | EA | ½” | 90 | 45 | 83.5 | 370 | 60 |

| T 250-40 | P / X / Y / A | EA | 1” | 350 | 45 | 125 | 461 | 60 |

| T 600-40 | P / X / Y / A | EA | 1½” | 800 | 45 | 125 | 537 | 60 |

LOW PRESSURE FILTER

♦ Very low installation clearance - Install anywhere

♦ Oil Removal (Coalescing) and Particulate

♦ Flow from 100 to 1810 m3/hour

♦ Particle Removal 0.01 (μm)

♦ Max. Oil carryover 0.003 (mg/m3)

Specification

| Description | Element Grade | |||

| P | X | Y | A | |

| Filter Element | Borosilicate | Borosilicate | Borosilicate | Activated Carbon |

| Construction Material (T100 - T1810) | Aluminium Alloy Epoxy Powder Coating | Aluminium Alloy Epoxy Powder Coating | Aluminium Alloy Epoxy Powder Coating | Aluminium Alloy Epoxy Powder Coating |

| Particle Removal | 5 (μm) | 1 (μm) | 0.01 (μm) | 0.01 (μm) |

| Max. Oil carryover | 5 (mg/m3) | 0.5 (mg/m3) | 0.01 (mg/m3) | *Removes odour |

| Max. Working Temp. | 80oC | 80oC | 80oC | 80oC |

| Initial Pressure Loss | 0.03 (kg/cm2) | 0.06 (kg/cm2) | 0.1 (kg/cm2) | 0.06 (kg/cm2) |

| Pressure Drop for Element Change | 0.4 (kg/cm2) | 0.4 (kg/cm2) | 0.4 (kg/cm2) | 0.4 (kg/cm2) |

| Element End Cap Colour | Green | Red | Yellow | Black |

MEDICAL VACUUM FILTERS

♦ Borosilicate filter element 99.999% efficiency

♦ Compliant with HEALTH TECHNICAL MEMORANDUM 2022

♦ Lightweight, corrosion-protected aluminium body

♦ Differential pressure gauge indicator for filter element replacement

♦ Sterilisable drain flask to capture biological fluids

♦ Vacuum flow rates from 3 to 68 litres/second

♦ Available in ½” to 3” pipe connections

Technical Specifications

| Model | Item Code | Flow rate at atmospheric pressure | Pipe Connection | Housing Dimensions (mm) | Spares - Item Code | ||||

| scfm | Nl/s | BSP | A | B | C | Spare Kit Filter Element | Draft Flask 100ml | ||

| T100 V | PFV07 | 7 | 3 | ½” | 87 | 294 | 170 | AS701 | |

| T250 V | PFV08 | 18 | 9 | 1” | 114 | 399 | 170 | AS693 | |

| T600 V | PFV09 | 44 | 21 | 1½” | 114 | 474 | 170 | AS697 | AC249 |

| T851 V | PFV10 | 63 | 30 | 2” | 148 | 666 | 170 | AS717 | |

| T1210 V | PFV11 | 89 | 42 | 2” | 148 | 736 | 170 | AS721 | |

| T1810 V | PFV12 | 134 | 63 | 3” | 211 | 761 | 170 | AS913 | |